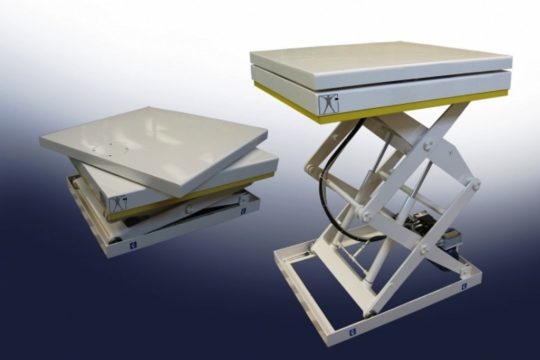

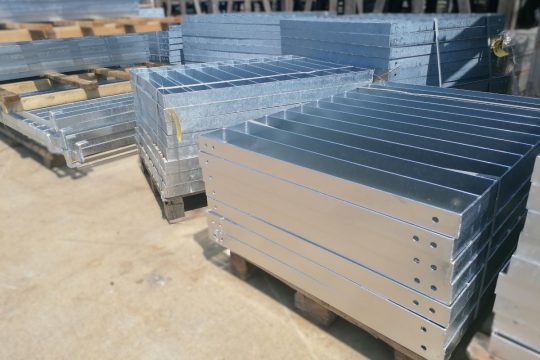

Welded steel parts

We produce steel components according to the customer’s design. According to the different needs we produce both the single parts and the complete welded frames. We are focused on small and medium series productions. If required we can machining the parts after welding and assemble the frame and test them. Finally, we can satin-finish the aesthetic parts.

Our focus is on tube processing thanks to dedicated systems such as 3D laser cutting, tube bending and calender. We also have machines for sheet metal working (laser cutting, bending and calender), and for ISO3834 certified welding.

Through a network of qualified suppliers we guarantee painting, galvanizing, mechanical processing and heat treatment services. Instead internally we have an assembly department made up of 4 technicians. We assemble mechanical, pneumatic and electrical components; we perform functional tests.

If necessary, we support the customer with our technical office to industrialize the product and to produce prototypes.

The sectors in which we are present are many, including:

- Brackets and frames for agricultural machinery,

- Frame for construction and earthmoving machinery.

- Hydraulic tanks

- For the petrochemical sector and heat exchangers.

- For fitness and body care machines.

- Stainless steel components for food and poultry plants

- Aluminum components for electric vehicles

- Components for private and public construction

- Street furniture