Quality control

The quality department is focused on the correct execution and repeatability of production. Controls take place throughout the production process: from laser cutting of tubes and sheet metal, to bending and calendering. From welding, assembly and surface treatments (painting and galvanizing).

We are ISO3834-3 certified for welding and all related processes. The certification is valid for construction steels S235 to S900MC.

We have also been ISO9001:2015 certified since 2023

in particular:

- the acceptance and traceability of the raw material (with the digital archive of certificates in 3.1) and of the sub-supply components.

- in production with dimensional and mechanical control. Also supported by 3D measuring tools connected directly to the drawings designed by the technical office.

- during assembly with verification through functional tests and personalized tests, according to the checklists shared with customers.

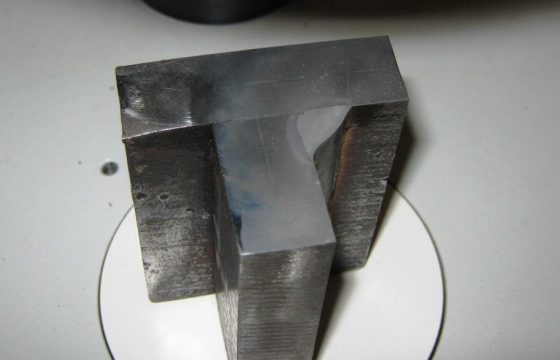

- Performing macrographic analyzes and non-destructive checks of welds (penetrating liquids or electromagnetic yoke techniques)

- Testing the welding process with micrographic analysis (through the Nital attachment) and digital archiving of the results using a stereoscope.

- Paint control thanks to sample verification of thickness, brilliance (measured in gloss), adhesion to the substrate and resistance to salt spray (rust).

- Checking the packaging in those cases where the customer’s product is shipped directly to the end user.

Our quality policy: