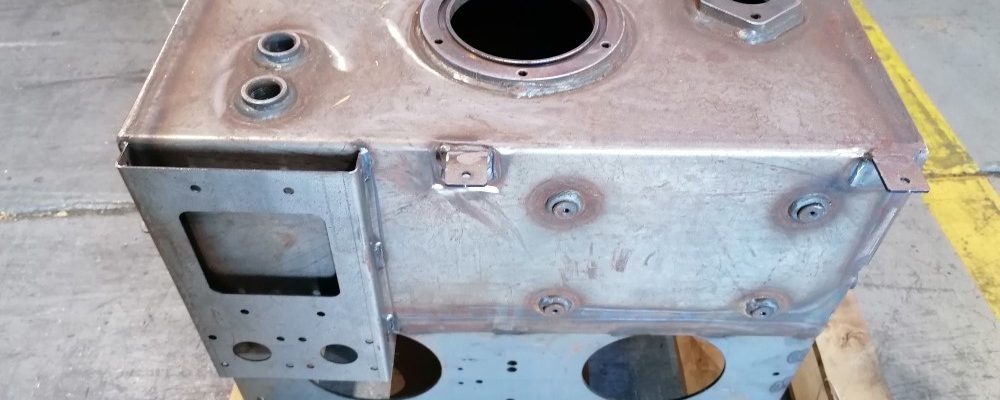

Hydraulic tanks

The hydraulic tanks are a fundamental part for every hydraulic power unit. In fact, they protect the circuit from external bodies and impurities through the filters. They also allow the cooling of the system, possibly assisted by the radiator if the mass cooling is not sufficient.

We manufacture custom-made sheet metal tanks; for non-pressure use. All our products are tested, cleaned and certified to ensure their durability and the absence of leaks during operation.

Our tanks are used in hydraulic power packs, and as fuel tanks (diesel and petrol), for water, for air, for vacuum, and for pressurized paints.

The design for hydraulic tanks

We offer a free support service for the design of new tanks. At the end of the development process, we provide the customer with all three-dimensional construction drawings and the various technical data sheets of the assembled products (for example filters, pressure gauges, caps).

The sizing of a tank within a hydraulic system is essential. To do this, it is important to know if the system works in continuous or occasional service, and to know the maximum flow rate of the pump. At this point, the tank capacity can be evaluated empirically by multiplying the flow rate 4 times in the case of continuous service, only 2 times in the case of service on request.

The raw material

Depending on the field of use and specific customer requests, we can use the following materials: pickled sheet metal, pre-galvanized sheet metal, stainless steel or aluminum alloys. Similarly, with the same variance of material, turned parts such as sleeves and threaded bushings are produced.

All our materials are certified according to EN 10204 – 3.1 and we guarantee their full traceability.

Production of hydraulic tanks

The entire production process follows the requirements dictated by the ISO3834-3 standard of which the company is certified.

The machining begins with the laser cutting of the components. To improve cutting cleanliness and limit thermal alteration of the edge, we use nitrogen and not oxygen as the cutting gas. The limited thermal alteration has significant benefits during the subsequent welding and painting phase.

Then we move on to the bending or calendering phase, depending on the prescribed shape, and to the caulking of the edge in preparation for welding.

After the necessary checks (according to the technical and welding specifications) prescribed by the ISO3834 standard, the assembly proceeds by continuously welding the various parts. The techniques used are MIG-MAG (wire welding) or TIG.

The testing

Once the welding phase is completed, the following checks are carried out and recorded on all the hydraulic tanks:

- Dimensional

- Aesthetic

- leak test (bubble test) at 0.5 bar. UNI EN ISO 9712.

- Finally, cleaning is carried out to eliminate any residues of oils and shavings created in the previous processing phases.

Painting

We offer different painting options to adapt to the specific requests of different clients. As a standard we offer a cycle that includes sandblasting, washing, the anti-rust primer and finally the powder finish with the color of your choice. An enamel paint can be applied as an alternative to the powder.

For aluminum or stainless steel tanks we also offer polishing or satin finishing treatments.

The assembling

After painting, we can complete the product by pre-assembling the filters, caps, fittings, pressure gauges, level indicators and hydraulic pumps on behalf of the customer. So as to transform our tanks into real hydraulic power units ready for installation.

At the conclusion of the assembly, we are able to test the tank by verifying its functionality according to a check list shared with the customer and pack it according to specific packaging lists.

The certifications

Our non-pressurized tanks do not fall under the PED 2014/68 / EU regulation which is part of the machinery directive. However, all welds are certified according to the ISO3834-3 standard, while the materials according to the EN 10204 – 3.1 standard