The manual sander machine is used for finishing stainless steel sheets, after welding and pickling.

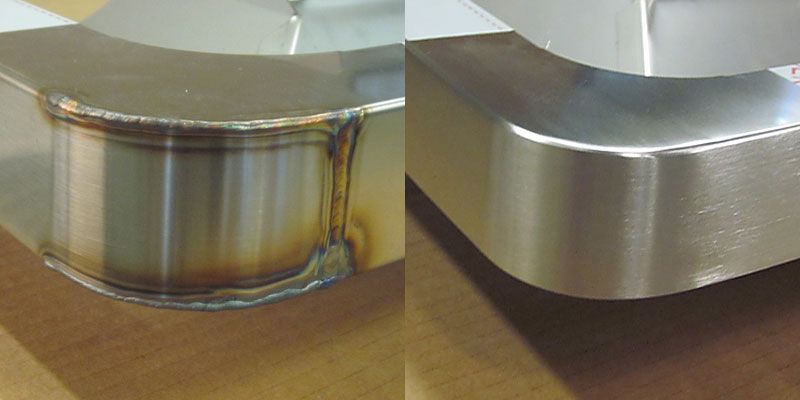

The satin finish allows the elimination of the halos produced by TIG welding on stainless steel. For optimum effectiveness it must be combined with chemical pickling of the weld seam. In fact, pickling eliminates the burnt halo that is created around the weld bead.

By doing this, a uniform surface is obtained for a more pleasant and captivating visual effect. It is necessary for aesthetic details and furnishing accessories.

Depending on the desired effect, it is possible to use different satin rollers, with different roughness (grain), so as to obtain a more glossy or opaque effect.

If the piece does not need to be welded, it is possible to work satin sheets already covered with a protective film (scotch brite). In this case, after the cutting and folding operation, the film is removed and the piece is ready and perfect.

We perform satin finishing only for small series productions or for prototypes. For larger batches it is necessary to prepare an automatic sander finishing machine. In our case we use specialized suppliers. They are third-party companies solely focused on these types of processes, such as: satin finishing, polishing, tumbling and chrome plating.

Agrital

We are a metalworking company active since 1972. We started in the agricultural mechanization sector with the construction of tractor cabins.

Today, thanks to a staff of over 50 people, we are present in various product sectors, mainly producing driver’s cabins, hydraulic tanks and hoods. In addition to having been the forerunners since 2003 in laser tube processing.