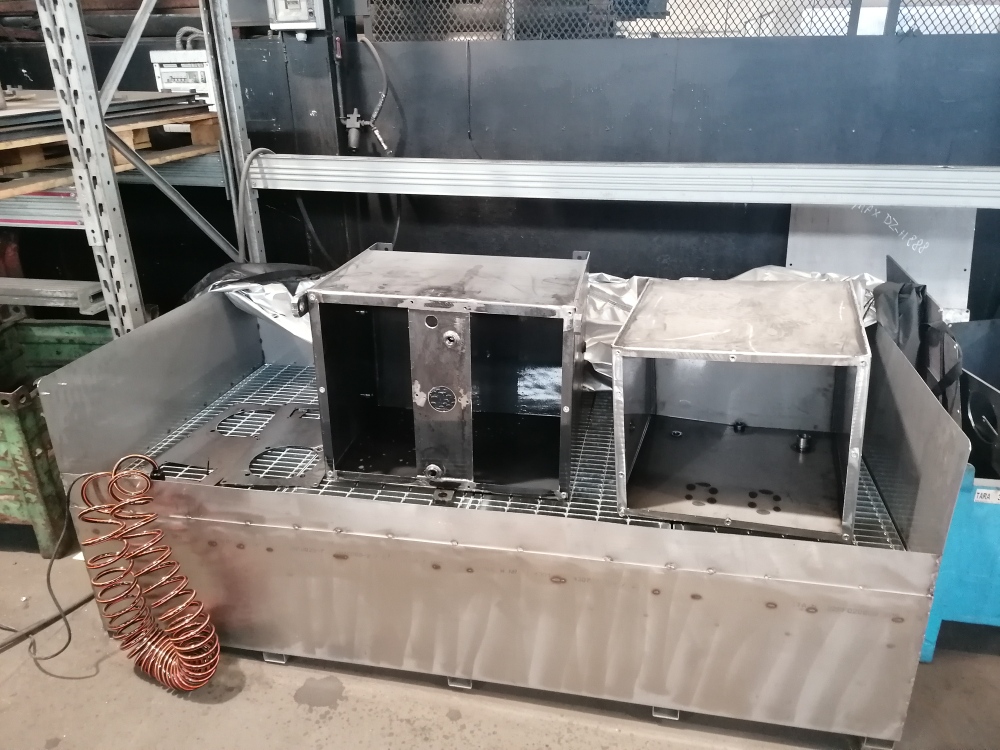

Internal cleaning of hydraulic tanks

After welding we carry out internal cleaning of the hydraulic tanks. This is a chemical wash, also known as tank flushing, and is applied to all the tanks we produce.

Why wash?

This process guarantees the total removal of residues inside the tank; which may have been generated by welding or mechanical processing (for example threading). Washing is especially useful for all those models that are completely closed, i.e. that do not have a screwed cover.

Cleaning hydraulic tanks is essential for their correct functioning. Introducing impurities into the hydraulic circuit can lead to damage to the gaskets, oil seals, cylinder rods and even failure of the hydraulic motors themselves.

The washing

To wash we apply a particular liquid, introduced with light pressure. Product has been specifically designed and tested in collaboration with the manufacturing company. A cleaning cycle, based on the size and complexity of the tank, can vary from 10 to 20 minutes. The product is certified not to leave unwelcome corrosive effects inside the tank itself once the liquid has been removed.

After that drained liquid is collected in a tank and filtered before reuse in order to guarantee maximum effectiveness with each wash. The life cycle of the product is approximately 20 washes.

Control

The washed tanks are inspected on a random basis to verify the Qualityquality of the cleaning. A visual check is carried out and one by applying magnets to check for any impurities captured. The impurities must be lower than our acceptability criterion in both size and density. Finally we check that the liquid has been completely drained. In normal conditions the check takes place every 10 tanks, i.e. at half the theoretical life of the washing liquid and at the end of its life.

Agrital

We produce customized hydraulic tanks, our current production exceeds 1000 units per year. For each tank, the watertightness is verified through the bubble test and cleanliness is guaranteed through chemical washing.

We are a metalworking company active since 1972. We started in the agricultural mechanization sector with the construction of tractor cabins.

Today, thanks to a staff of over 50 people, we are present in various product sectors, mainly producing driver’s cabins, hydraulic tanks, railings and hoods (metal casing). In addition to having been the forerunners since 2003 in laser tube processing

The production workflow

![]()